When pipelines need maintenance or upgrades, shutting down an entire system isn’t always possible. For municipalities, utilities, and facilities, a full shutdown can mean costly downtime, service interruptions, and unhappy customers. That’s where bypass piping comes in — a temporary solution that reroutes flow around the work zone, keeping systems live and uninterrupted.

At Watertap Inc., bypass piping is part of our municipal pipeline services It’s a reliable way to complete repairs, tie-ins, and emergency projects without taking your system offline.

What Is Bypass Piping?

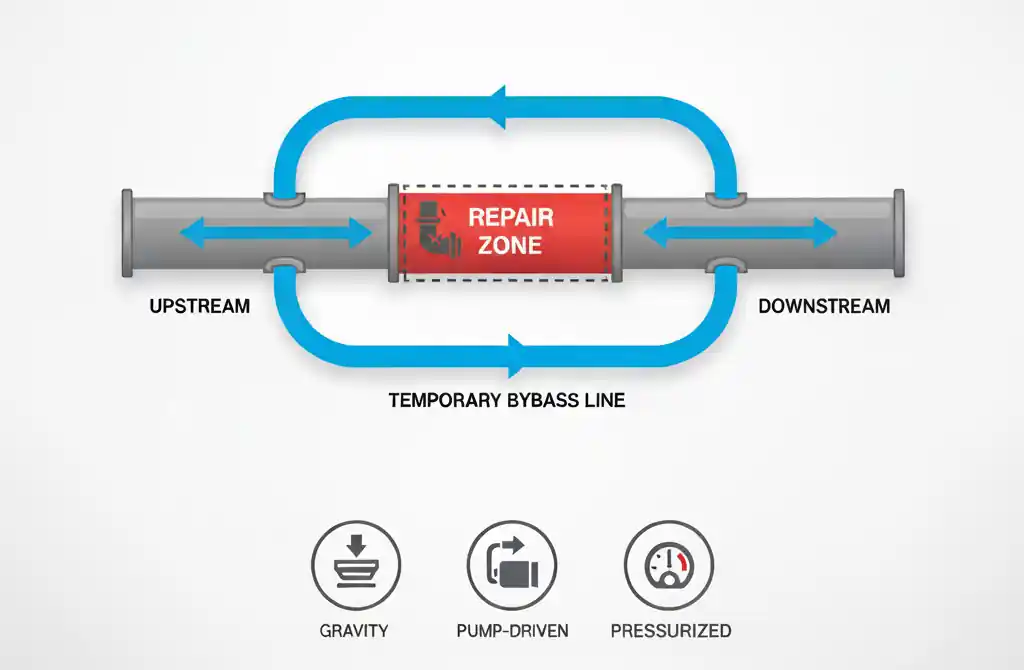

Bypass piping works like a detour for your pipelines. Instead of shutting down the system, crews install a temporary piping setup that keeps flow moving while maintenance is performed.

Depending on the type of system, bypass piping may include:

- Gravity bypasses – common in sewer systems, where flow naturally follows slope into a temporary line

- Pump-driven bypasses – using pumps to move sewage or low-pressure fluids around the work area

- Pressurized bypass setups – temporary above-ground piping for live water mains and other pressurized lines, often paired with line stopping or valve insertions to keep service online.

When Do You Need Bypass Piping?

Bypass piping is commonly used in situations where systems must remain operational. Municipal water main upgrades often rely on temporary bypasses to keep residents supplied while tie-ins or replacements are completed. Sewer rehabilitation projects use bypasses to reroute flow during relining or slip-lining. In pressurized systems, bypasses support valve insertions and emergency repairs by maintaining flow while crews work under pressure. Beyond municipal work, bypass piping is also valuable for industrial and commercial systems such as chilled water and glycol loops, where downtime can disrupt entire facilities.

Benefits of Bypass Piping

Bypass piping provides clear advantages for municipalities, utilities, and facilities:

- Service continuity – essential for hospitals, schools, manufacturing plants, and citywide systems

- Cost savings – prevents lost revenue and avoids expenses tied to shutdowns and restarts

- Environmental protection – keeps wastewater systems under control, avoiding spills or treatment plant overloads

- Flexibility – adaptable to different pipe sizes, materials, and products, including water, sewer, glycol, chilled water, and compressed air

- Safety – maintains controlled flow and prevents uncontrolled discharges

Want to see how bypass compares with other options? Check out our Line Stopping vs. Hot Tapping guide.

How Watertap Handles Bypass Piping

Our team specializes in no-shutdown pipeline solutions, and bypass piping is a core part of that work. We design each setup to fit the specific needs of the project, whether it involves a municipal water main, a sewer system, or an industrial process line. By integrating bypass piping with services like line stopping and valve insertions, we give clients complete flexibility to maintain flow while performing upgrades or repairs. Our crews are experienced across multiple pipe materials — cast iron, ductile iron, HDPE, copper, PVC — and handle diverse products including water, sewer, glycol, chilled water, and compressed air.

Learn more about our team and capabilities on our About Us page.

Real-World Example

During a recent line stopping project in Denton, TX, we installed a bypass system to keep water service online. Residents never experienced an interruption, and the utility avoided the costs of a full system shutdown.

Bypass piping is one of the most effective tools for maintaining service during water, sewer, and industrial pipeline maintenance. It prevents shutdowns, saves costs, and ensures essential services keep flowing — even during major repairs or emergencies.

For more insights, read our article on insertion valves: applications, types, and benefits

Contact Us Today For A Free Consultation