Key Points

- Hot tapping (also known as live tapping) enables new connections on pressurized pipelines without service interruption.

- Commonly used in water, sewer, and industrial systems for tie-ins, monitoring ports, and bypass connections.

- Prevents costly shutdowns, downtime, and service disruptions while maintaining pressure and safety.

- Often used with line stopping

Pipeline systems rarely get the luxury of downtime — especially when they deliver essential services like water and sewer. For utilities, municipalities, and industrial facilities, shutting down an entire line can mean costly disruptions and community impact. That’s where hot tapping, sometimes called live tapping, becomes invaluable.

Hot tapping allows crews to connect to a pressurized pipeline without interrupting service. It’s a safe and proven technique for adding new branches, monitoring points, or tie-ins to existing systems — all while the line stays live. In municipal water systems, hot tapping is often used to add monitoring ports or valve assemblies without interrupting service.

At Watertap Inc. we use hot tapping to help clients expand, upgrade, or repair infrastructure efficiently and safely, minimizing downtime while maintaining flow.

What Is Hot Tapping?

Hot tapping is the process of making a new connection on an active, pressurized pipeline without taking it out of service. Crews use a specially designed fitting, valve, and tapping machine that allow them to cut into the pipe while maintaining full control of pressure and flow.

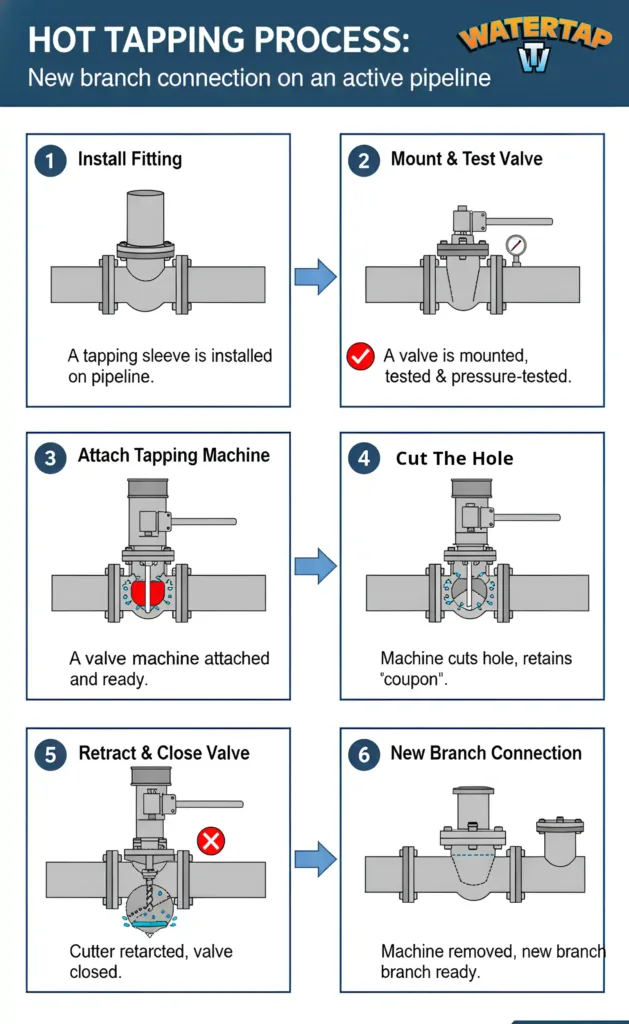

Here’s how it works:

- A tapping sleeve or fitting is securely installed on the pipeline at the desired connection point.

- A valve is mounted on that fitting and tested for integrity.

- The connection is pressure-tested to confirm a proper seal and ensure it’s leak-free.

- A tapping machine attaches to the valve and cuts a precise hole into the pressurized pipe.

- The small section of pipe removed — called the “coupon” — is retained by the machine’s pilot drill.

- Once the cut is complete, the valve is closed, and the machine is safely removed, leaving a new, fully functional branch connection.

This process avoids draining or depressurizing the system, allowing new tie-ins to be made safely while the line remains operational.

Learn more about how this compares with other live pipeline solutions in our Line Stopping vs. Hot Tapping guide.

Hot vs. Cold Tapping

The difference between hot tapping and cold tapping comes down to pressure. Cold tapping follows the same basic steps but is done on a depressurized or inactive line.

Hot tapping, by contrast, maintains internal pressure and continuous service throughout the entire operation — making it ideal for live systems that can’t be shut down.

For a detailed technical explanation, the EPA’s Pipeline Hot Taps guidance outlines how this process is used safely in pressurized pipeline work.

When to Use Hot Tapping

Hot tapping is used whenever maintaining service flow is critical. Typical applications include:

- Adding new branch connections to an existing water main

- Installing monitoring equipment, such as pressure gauges or sampling ports

- Creating tie-ins for new developments, pump stations, or bypass lines

- Connecting temporary service lines during major repairs or reroutes

- Performing controlled expansions in industrial cooling or process systems

Because the system stays pressurized, these connections can be made without disrupting service — a major benefit for municipalities, hospitals, and manufacturing facilities.

Learn more about bypassing methods in our Bypass Piping Explained article.

Benefits of Hot Tapping

Hot tapping offers major advantages for utilities and infrastructure operators:

- No shutdowns – flow continues uninterrupted

- Cost savings – avoids draining and repressurizing large systems

- Speed – shortens project timelines for tie-ins and upgrades

- Safety – uses specialized fittings and pressure-rated tapping machines

- Versatility – compatible with a wide range of materials and fluids

For additional insights into keeping live systems online, read Avoiding Shutdown During Pipe Maintenance.

Compatible with Hot Tapping

Hot tapping can be performed on most common pipeline materials, including:

Materials

- Cast iron

- Ductile iron

- Steel

- PVC

- HDPE

- Copper

- Asbestos cement (with proper safety protocols)

Campatible With

- Potable water

- Sewer and wastewater

- Glycol and chilled water

- Brackish water

- Compressed air

The American Water Works Association (AWWA) Manual M44 notes hot tapping’s versatility for live water distribution networks — from 2-inch laterals to large-diameter mains.

Some pipe types, like Prestressed Concrete Cylinder Pipe (PCCP), require specialized inspection and repair techniques rather than standard hot tapping. Learn more about our approach in the PCCP Services.

Hot Tapping vs. Line Stopping

Although hot tapping and line stopping are often mentioned together, they serve distinct purposes:

- Hot tapping creates a new live connection on a pressurized line.

- Line stopping temporarily isolates a section for maintenance.

In many projects, they work hand-in-hand: a hot tap may first install the valve that allows a line stop to be performed safely later on.

If you’re not sure which one fits your situation, see What Is Line Stopping?.

How Watertap Performs Hot Tapping

Watertap performs safe, precise, and efficient hot tapping services for water, sewer, and industrial pipeline systems.We use industry-standard fittings and equipment designed specifically for under-pressure connections, following the same proven practices established by leading manufacturers such as Mueller Co. and T.D. Williamson.

Every tap is engineered for the system’s pressure, diameter, and material, ensuring quality and safety.

We’ve completed live taps across a range of materials and sizes, helping municipalities and facilities expand infrastructure without costly shutdowns.

Learn more about our related Valve Insertion Services and how they complement hot tapping during larger pipeline projects.

For a broader look at pipeline maintenance planning, check out our Pipeline Maintenance Checklist.

You can also explore our team’s background on the About Us page.

Summary

Hot tapping allows utilities and facility managers to expand or modify their systems safely — without shutting down service. Whether adding new connections, monitoring points, or bypass lines, it’s one of the most efficient ways to maintain service continuity during upgrades or construction.

Contact Us Today For A Free Consultation